|

Services

Include

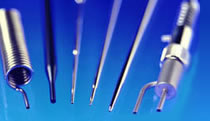

Abrasive Flow Honing Assembly Brazing Bending, Coiling, Forming Finishing, Coating Laser Processing Services Passivation, Cleaning Precision Cutting Precision Machining Swaging, Flaring, Bulging

ISO 9001:2008 |

Tubing Materials

304, 316, INCONEL, TITANIUM, ETC.

This page discusses the different materials used by New England Small Tube and their applications. The materials listed below are those that we have found to be the most popular for our customers, they do not represent the limits of what we can do. If you have an application that uses a material not listed below, please call us and we will do our best to help you.

STAINLESS STEEL

304

This grade of chromium-nickel stainless steel retains an untarnished silvery surface under atmospheric conditions and has excellent heat oxidation resistance up to approximately 1600 deg F. In the annealed condition it is non-magnetic. Although it cannot be hardened by heat treatment, its hardness and tensile strength may be considerably increased by cold working. Type 304 has a maximum carbon content of .08% in order to minimize susceptibility to intergranular corrosion which may result when the metal is heated to around 900 deg. F.

Because of its great ductility and exceptional toughness, it can be severely drawn, spun, rolled, machined or otherwise worked in the cold state. It's welding properties are outstanding. Type 304 is recommended for corrosive environments.

316

This chromium-nickel alloy has a low carbon and high nickel content, and contains 2 to 4% molybdenum. Its corrosion resistance is somewhat better than chromium-nickel grades without molybdenum (such as 304)-particularly in acidic environments. The molybdenum tends to increase passivity, improves the alloy's corrosion resistance in general, and helps minimize pitting or pin hole corrosion under certain conditions. This grade has good creep strength at elevated temperatures.

Type 316 is used principally in highly corrosive environments, especially those where sulphite or various dye and bleach solutions are used.

304L & 316L

Types 304L and 316L are extra low carbon alloys that offer better corrosion resistance adjacent to brazes. These alloys contain a maximum of only 0.03% carbon. This amount of carbon is small enough to eliminate harmful carbon precipitation adjacent to brazes during the brazing operation.

These extra low carbon grades are recommended only for equipment made for service below the lower sensitizing temperature of 800 deg. F - especially when corrosive conditions are severe. They are not recommended for use at high temperature. Both grades can be highly polished with no surface blemishes.

OTHER METALS/ALLOYS

BRASS

Brass is a copper alloy that contains zinc as the principal alloying element with or without other designated alloying elements such as iron, aluminum, nickel and silicon. Free-machining brass (the most common used by New England Small Tube) has excellent machinability and can be fabricated by machining, roll threading and knurling.

INCONEL 625

INCONEL alloy 625 has high strength and toughness from cryogenic temperatures to 2000 deg. F. It has high tensile, creep and rupture strength; outstanding fatigue; and high thermal-fatigue strength. In addition to good oxidation resistance, the alloy also resists corrosive attack by many other media; it is virtually immune to chloride-ion stress-corrosion cracking. INCONEL 625 is readily fabricated by common processes and has excellent brazeability qualities.

TITANIUM

Titanium has strength similar to austentic stainless steel, yet its strength-to-weight ratio is superior to almost all other metals. It is immune to corrosive attacks by salt water or marine atmospheres and it exhibits exceptional resistance to a broad range of acids, alkalis and industrial chemicals.

|

|